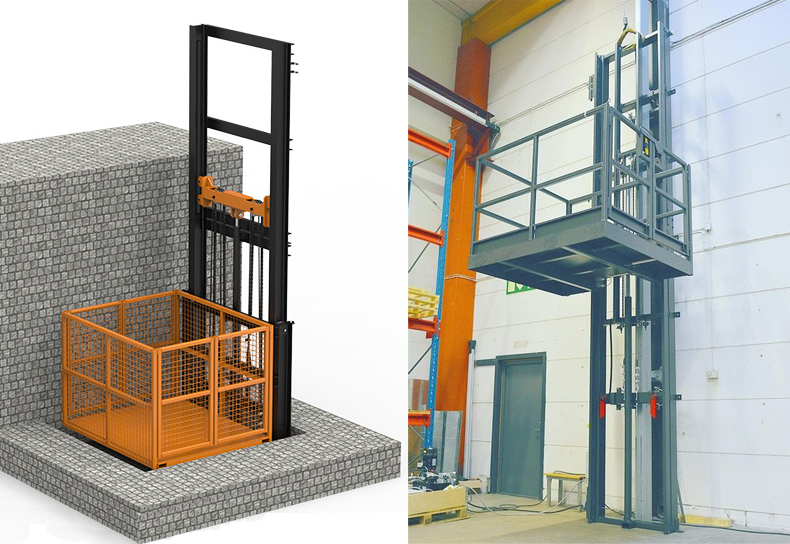

Product Description

The cargo lift elevator also called freight elevator, goods lift, mezzanine goods lift. It common used on factory, warehouse and mezzanine building.

The best solution for material handling from different floor.

Lifting Height

Customized from 1 meters to 8 meters.

Load Capacity

From 1 ton to 10 tons.

Platform Size

Customized as your request.

Why Use This Cargo Lift ?

1. Non-Pit installation. The cargo lift elevator no need extra engine room or big pit, platform directly fixed on the ground, save space.

2. Lower fault rates. Hydraulic driving with simple control system. Much lower fault rates than other complex elevator system.

3. Much more lower cost. Simple control system and simple structure will lower the total service cost. Especially suitable for some low budget project. You can do maintenancework by yourself, no need any professional engineer.

Single Rail Cargo Lift

Double Rail Cargo Lift

Cargo Lift With Steel Mesh Arounded

FAQ about Cargo Lift Elevator.

- What is a cargo lift elevator used for?

- What’s the typical weight capacity?

- What sizes are available?

- Where can it be installed?

- Are there safety features?

- How often does it need maintenance?

Regular checks (monthly/quarterly) of motors, cables, and brakes to ensure safe, efficient operation.

-

What safety features must a qualified cargo lift have?

Contact Us For A Quote